We produce nearly 100 neutron tubes per year, and these are used by a wide variety of companies or research institutes in more than 40 countries around the world, reinforcing our position as the world leader in this market.

We also develop and produce neutron generators for the French nuclear deterrence, which require an extraordinary level of technological skill.

Neutron tubes

Neutron generators are mainly used for industrial applications such as nuclear fuel waste management or for scientific purposes.

Manufactured around a sealed, metal vacuum and a ceramic enclosure, the Sodern tube features:

- A Penning-type ion source,

- A gas tank,

- A VHV particle accelerator field,

- A target.

The Sodilog tube, a tube which has been specially designed for oil drilling, is very reliable thanks to a unique combination of ceramic technology and an equimolar loading of deuterium and tritium gases, which also makes it highly resistant to high temperature operations.

Neutron activation operates as follows: a neutron source generates neutrons which interact with the atoms. This reaction provokes gamma radiation which, once analyzed, will enable the elements and their concentration to be defined.

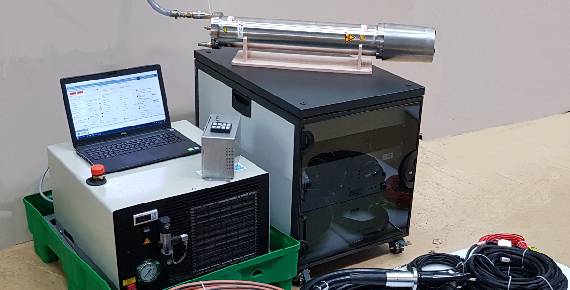

Composition of a neutron generator:

- An accelerator head,

- A very high voltage power supply,

- A command unit,

- A dedicated software.

Around the neutron tube

Neutron emission module (NEM): all of the mechanics needed to hold and encapsulate the neutron tube

Used mainly for research, by universities or the Atomic Energy Commission, which need NEM outside the CNA.

Genie 16NG

Contains a command unit, a high voltage power supply to lead the current into the metal parts of the resin part, a control computer.

Genie 35

Contains a proximity command unit, a high voltage power supply to lead the current into the metal parts of the resin part, a control computer.

The generator (neutron system): NEM, all the control electronics and electrical power supply for the NEM